Embossing Hologram Dies

Price 500 INR/ Piece

MOQ : 1 Piece

Embossing Hologram Dies Specification

- Working Process

- High precision CNC machining, EDM, Polishing

- Mould Base

- Imported tool steel

- Core Material

- Hardened Steel

- Life Span

- Up to 200,000 cycles

- Tolerance

- 0.005 mm

- Material

- Nickel/Steel

- Shaping Mode

- Embossing

- Punch Dies

- Hardened and tempered for extended life

- Die Head

- Custom CNC fabricated

Embossing Hologram Dies Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 500 Pieces Per Day

- Delivery Time

- 3 Days

About Embossing Hologram Dies

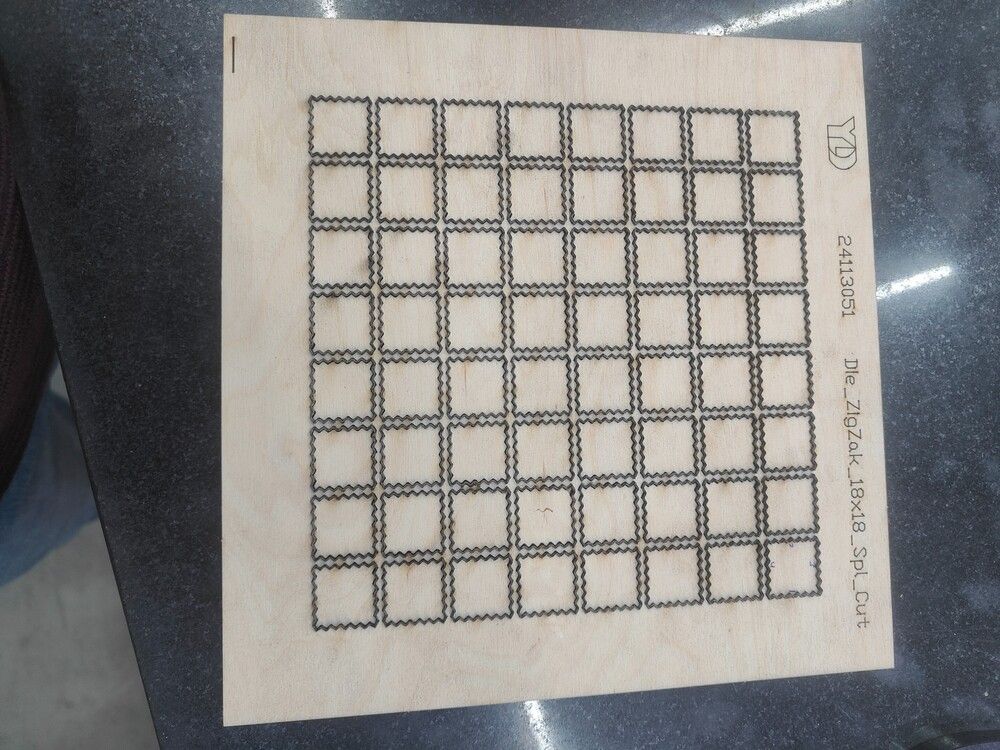

These Embossing Hologram Dies are mainly used for making holograms and accurate cutting work is done only through laser technology. These are made under the instructions of our well-experienced professionals, by using the sophisticated tools & techniques and finest quality raw materials, in compliance with the international standards. These are highly appreciated for their elegant quality, superb performance, and high strength. Furthermore, we are supplying the range of Embossing Hologram Dies in various specifications at market leading prices.

Engineered for Precision and Durability

Built with imported tool steel and nickel/steel core material, these hologram dies feature a hardened surface (HRC 48-52) for excellent wear resistance. They maintain their form and flawless high-gloss finish over extensive production runs-making them highly cost-effective for large-scale packaging and security applications.

Advanced Manufacturing Process

Every die undergoes chemical etching and precision engraving using high-tech CNC machining and EDM processes. Each piece is then polished to achieve a flawless mirror finish, ensuring crisp embossing details and sharp hologram effects every time.

Broad Application and Compatibility

Our dies are designed for versatility, suitable for use on PET, PVC, and BOPP films. They support diverse applications ranging from security labels to hot stamping on luxury packaging, making them ideal for various sectors including manufacturers, suppliers, and wholesalers.

FAQ's of Embossing Hologram Dies:

Q: How are Embossing Hologram Dies manufactured for optimal performance?

A: These dies are produced using cutting-edge chemical etching and high-precision CNC machining methods, followed by polishing and EDM processes that ensure consistent pattern depth and a flawless mirror finish. The combination of imported tool steel and hardened core materials enhances their durability and operational life.Q: What types of films are compatible with these embossing dies?

A: Our dies are specifically designed for use with PET, PVC, and BOPP films. This allows for flexible application across different packaging and security label requirements, guaranteeing excellent imprint quality on each substrate.Q: Where can these hologram dies be applied?

A: They are ideal for hologram hot stamping, security labels, branded packaging, and other anti-counterfeiting needs. Their superior finish and customizable design make them widely used by manufacturers, retailers, suppliers, and traders, particularly in the packaging and labeling industries.Q: What is the lifespan and heat resistance of the dies?

A: Each die is capable of up to 200,000 cycles and can withstand processing temperatures up to 350C, ensuring prolonged performance even under demanding production conditions.Q: How does the customization process work for client designs?

A: Clients can provide their unique patterns or specifications. Our team utilizes high-precision engraving and CNC technology to produce dies tailored to individual needs, ensuring that each design is replicated with great accuracy.Q: What are the benefits of using high-gloss, mirror finish embossing dies?

A: The high-gloss, mirror finish not only enhances the visual appeal of the hologram effect but also ensures clear, sharp pattern definition, which is essential for applications like security marking and luxury packaging.Q: What is the size range supported for embossing?

A: Embossed areas can be crafted up to 300 x 300 mm, accommodating a broad array of packaging and labeling requirements for manufacturers and suppliers.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hologram Dies Category

Label Hologram Dies

Price 500 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Brown

Material : Metal

Usage : Industrial

Product Type : Label Hologram Dies

20 x 11 Hologram Dies

Price 500 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Gray

Material : Metal

Usage : Industrial

Product Type : Hologram Dies

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free