Paper Cup Dies

Price 500 INR/ Piece

MOQ : 1 Piece

Paper Cup Dies Specification

- Tolerance

- 0.01 mm

- Core Material

- Stainless Steel

- Working Process

- CNC Finishing, Heat Treatment

- Mould Base

- Steel or Hardened Alloy

- Life Span

- Up to 8 Million Strokes

- Material

- High-Grade Steel

- Shaping Mode

- Punching Mold

- Punch Dies

- Precision Ground Tool Steel

- Die Head

- Multi-Cavity

Paper Cup Dies Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 500 Pieces Per Day

- Delivery Time

- 3 Days

About Paper Cup Dies

Our provided range of Paper Cup Dies are largely used for making paper cups and die cutting applications. These are manufactured by utilizing supreme quality raw materials and innovative technology under the stern guidance of our experts. These are extremely admirable by our customers for their high performance and robust construction. Furthermore, we provide these Paper Cup Dies in different specifications at very nominal rates.

Precision Manufacturing and Reliable Performance

Utilizing CNC finishing and advanced heat treatment, these dies deliver consistent cup formation with minimal maintenance requirements. The multi-cavity die head and precision-ground punch dies enhance output rates, achieving speeds of 200 to 450 cups per minute. Each die is crafted for optimal compatibility with paper cup forming machines, offering unparalleled efficiency and reliability for manufacturers and suppliers.

Versatile Design and Customization Options

Available in both single and multi-cavity configurations, as well as customized designs, these paper cup dies can accommodate various production scales and cup sizes. Choices in steel or hardened alloy mould bases and standard export-grade wooden box packaging ensure safe transport and storage. Custom-built solutions can be tailored specifically for retailers, wholesalers, and traders across India.

FAQ's of Paper Cup Dies:

Q: How are the paper cup dies maintained for optimal performance?

A: Minimal maintenance is required for these dies due to their polished, rust-proof finish and high-grade construction. Regular lubrication ensures smooth operation and extends die life up to 8 million strokes.Q: What cup sizes do the dies support, and are custom sizes possible?

A: The dies are compatible with cup sizes ranging from 40 ml to 500 ml. Custom designs can be implemented based on specific requirements, offering flexibility for unique applications.Q: When should lubrication be applied to these dies?

A: Lubrication should be applied regularly during operation to further reduce wear and maintain smooth performance, especially during extended production runs at high speeds.Q: Where are these paper cup dies suitable for use?

A: These dies are designed for paper cup forming machines in manufacturing setups, suitable for use by manufacturers, retailers, suppliers, traders, and wholesalers across India.Q: What is the process used in manufacturing these dies?

A: CNC finishing and precision heat treatment are employed to achieve exacting tolerances (0.01 mm). The die head features multi-cavity design, and punch dies are made from precision ground tool steel for optimal durability and accuracy.Q: What are the benefits of using these paper cup dies?

A: Key advantages include high production speed (200-450 cups/minute), extended life span, minimal maintenance, compatibility with various machines, and the ability to customize according to user needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Packaging Box Dies Category

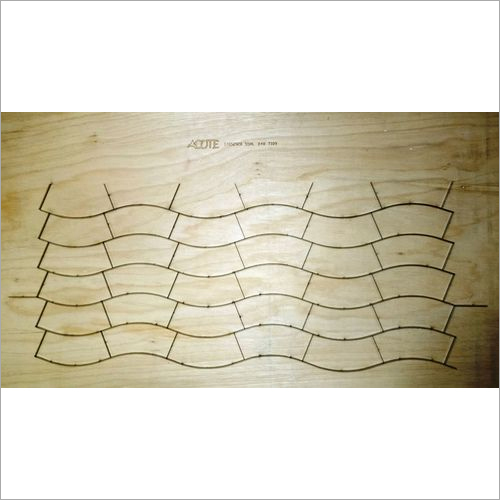

Zig Zag Special Shape Dies

Price 500 INR / Piece

Minimum Order Quantity : 1 Piece

Shaping Mode : Other, Compression Mould

Punch Dies : Interchangeable Inserts

Core Material : Alloy Tool Steel

Tolerance : 0.01 mm

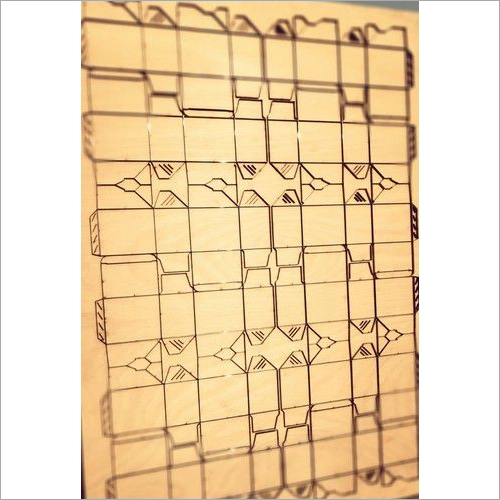

Carton Box Dies

Price 500 INR / Piece

Minimum Order Quantity : 1 Piece

Shaping Mode : Other, Die Cutting

Punch Dies : Multiple Cavity

Core Material : High Carbon Steel

Tolerance : 0.01 mm

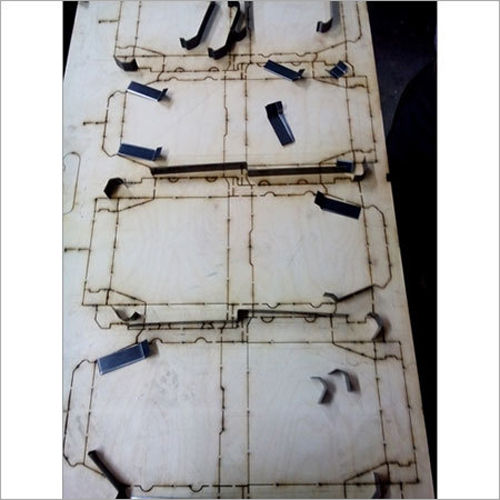

Corrugated Pizza Box Dies

Price 500 INR / Piece

Minimum Order Quantity : 1 Piece

Shaping Mode : Other, Die Cutting

Punch Dies : High Precision

Core Material : Alloy Steel

Tolerance : 0.01 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free