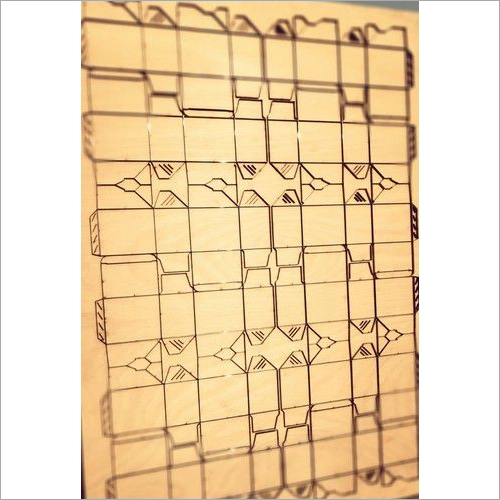

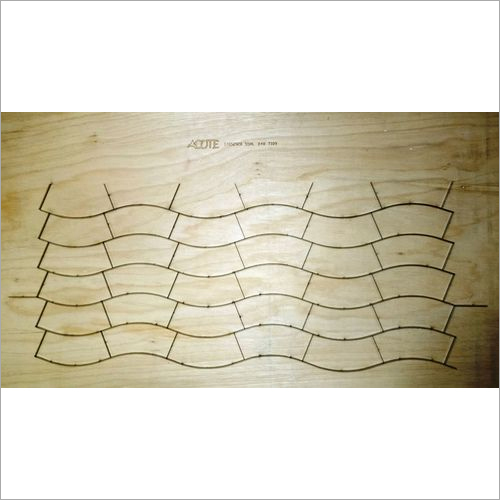

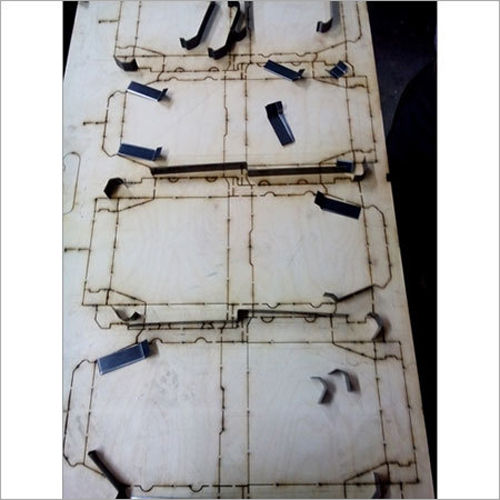

Zig Zag Special Shape Dies

Price 500 INR/ Piece

MOQ : 1 Piece

Zig Zag Special Shape Dies Specification

- Working Process

- Precision CNC Machining

- Life Span

- Up to 100,000 Cycles

- Mould Base

- High-grade Steel Plate

- Tolerance

- 0.01 mm

- Core Material

- Alloy Tool Steel

- Material

- Superior Grade Steel

- Shaping Mode

- Compression Mould

- Punch Dies

- Interchangeable Inserts

- Die Head

- Custom Zig Zag Profile

Zig Zag Special Shape Dies Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 500 Pieces Per Day

- Delivery Time

- 3 Days

About Zig Zag Special Shape Dies

Zig Zag Special Shape Dies are used in manufacturing corrugated and other types of boxes. These are manufactured using supreme grade quality components that is sourced from reliable vendors of the market keeping in mind set industry norms. These are preferred by using large quantity of clients because of their excessive high-quality and tremendous functions. Clients can avail these Zig Zag Special Shape Dies from us in various standard specifications.

Engineered For Precision and Durability

Our Zig Zag Special Shape Dies are meticulously designed with advanced die heads featuring a special zig-zag contour. Utilization of precision CNC machining and superior heat treatment processes ensures long-lasting performance. High resistance to wear, combined with a robust mould base and integrated cooling, facilitates reliable results and extended tool life in industrial production.

Applications Across Key Industries

Suitable for sheet metal forming and electrical stamping, these dies are an asset in automotive, electrical, appliance, and general metalworking sectors. The interchangeable inserts and custom cavity options make them versatile for tailored production requirements, supporting both large-scale and specialized manufacturing processes.

FAQ's of Zig Zag Special Shape Dies:

Q: How are these Zig Zag Special Shape Dies manufactured to achieve high precision?

A: These dies are produced using precision CNC machining processes, ensuring tight tolerances of 0.01 mm. Superior grade alloy tool steel is vacuum hardened and finished with polishing or nitriding, which results in high dimensional accuracy and consistent performance.Q: What are the main benefits of the special zig-zag contour design?

A: The custom zig-zag contour enables complex part shaping, enhances form fidelity, and optimizes material flow during sheet metal forming and electrical stamping, resulting in better-quality end products and reduced process defects.Q: When should I choose single or multi-cavity options?

A: Single-cavity dies are ideal for lower production volumes or prototyping, while multi-cavity options are recommended for higher output needs, maximizing efficiency and reducing operational times in mass production.Q: Where can these dies be used in terms of industry applications?

A: These dies are extensively used in automotive, electrical, appliance, and general sheet metal industries, where complex profiles, high precision, and longevity are critical.Q: What is the expected lifespan of these dies, and what factors influence it?

A: The dies are rated for up to 100,000 cycles. Actual lifespan can depend on factors such as material type, operating conditions, and adherence to recommended maintenance routines.Q: How does the integrated cooling system benefit die operation?

A: Integrated cooling channels reduce heat buildup during use, maintaining tool hardness, ensuring dimensional stability, and extending die life, which is especially important in high-volume production settings.Q: Can these dies be customized to suit specific production requirements?

A: Yes, full customization is available as per client drawings, including contour geometry, cavity numbers, and functional inserts, ensuring compatibility with unique production needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Packaging Box Dies Category

Carton Box Dies

Price 500 INR / Piece

Minimum Order Quantity : 1 Piece

Working Process : Other, Precision CNC Machining

Punch Dies : Multiple Cavity

Die Head : Hardened Tool Steel

Mould Base : Steel

Paper Cup Dies

Price 500 INR / Piece

Minimum Order Quantity : 1 Piece

Working Process : Other, CNC Finishing, Heat Treatment

Punch Dies : Precision Ground Tool Steel

Die Head : MultiCavity

Mould Base : Steel or Hardened Alloy

Corrugated Pizza Box Dies

Price 500 INR / Piece

Minimum Order Quantity : 1 Piece

Working Process : Other, Cutting, Creasing, and Forming

Punch Dies : High Precision

Die Head : Interchangeable

Mould Base : Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS